Call Us

08045478157Band Sealing Machine

Product Details:

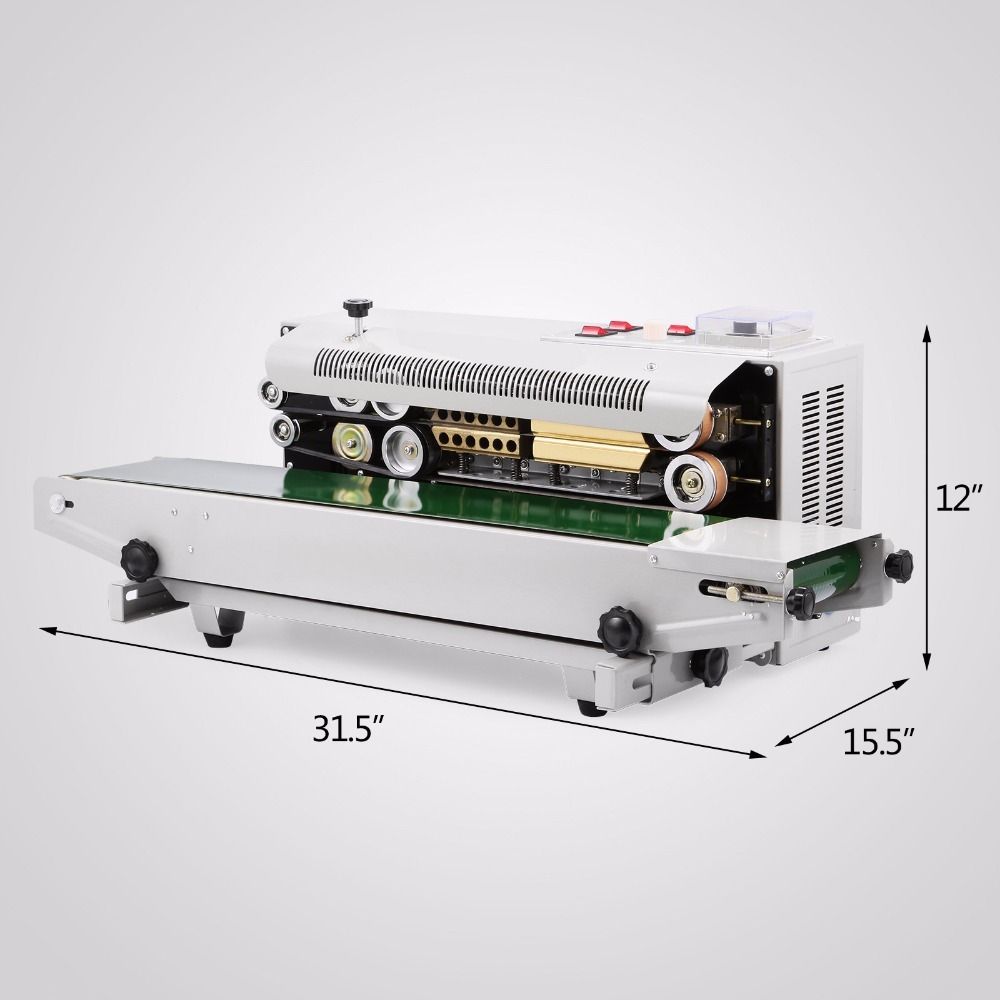

- Dimension (L*W*H) 800 x 400 x 305 Millimeter (mm)

- Power 650 Watt (w)

- Application Sealing Plastic Bag / Pouches

- Automation Grade Semi Automatic

- Color Milky White & Green

- Type Horizontal Band Sealer

- Sealing Speed 0 ~ 12 Mtr. / Min

- Click to View more

Band Sealing Machine Price And Quantity

- 15700 INR/Piece

- 1 Piece

Band Sealing Machine Product Specifications

- 19 Kilograms (kg)

- 220 Volt (v)

- Sealing Plastic Bag / Pouches

- 100 %

- 650 Watt (w)

- 0 ~ 12 Mtr. / Min

- 800 x 400 x 305 Millimeter (mm)

- Horizontal Band Sealer

- Milky White & Green

- New

- Semi Automatic

Band Sealing Machine Trade Information

- Kolkata

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 7 Piece Per Week

- 3 Days

- Yes

- Contact us for information regarding our sample policy

- Standard

- Asia, Africa

- All India, East India, Arunachal Pradesh, Bihar, Chhattisgarh, Jharkhand, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Sikkim, Tripura, West Bengal, Assam

Product Description

Continuous Band Sealer (VP 900 H-MS)

Introduction

It is newly designed on the basis of many years' experience of manufacturing sealing machine & the newest market demand. It is an economic series' model of Continuous Band Sealer, which is ideal for heat sealing of a variety of thermoplastic pouches and bags, is in the function on continuous carry, seal in one operation, and can reduce the labor intensity of operators. It has advantage of safe and easy operation, speedy & accurate sealing. This particular model is available in Horizontal Configuration. It is widely preferred due to efficient packaging of both perishable and non-perishable products in terms of protection from potential damages and contamination before reaching at the hand of end customers. It adopts electronic constant temperature control system and step less speed adjusting transmission mechanism. As an optional attachment,Solid ink wheel, which is provided, can print production date as well as sealing. The printing letters are clear, have available colours, dries immediately & easy to change.

Salient Features / Benefits

- Simple Design & Sturdy Construction

- MS Body

- Horizontal Sealing

- Low Maintenance

- High Productivity

- Reliable Sealing Quality

- Very Low Power Consumption

- Suitable for Pack Size of up to 2 Kgs

- Suitable for All Type of Heat Sealable Material in Every Thickness

- Increased Shelf Life of Packaged Product

Advantages

Due to automation, Continuous Band Sealer is able to increase production dramatically. On an average, 20 to 30 plastic bags / pouches can be sealed in a minute. Sealing speed will depend upon operators' efficiency.

It can give output equivalent to 3-4 Manual Sealing Machines thus there is great savings in labour cost.

This machine is imported from Taiwan including best parts, components. It is manufactured in the highly developed manufacturing unit in using latest technology. Machines' quality is strictly controlled in various levels of manufacturing based on range critical parameters. Hence quality is assured for continuous,excellent & prolonged machine performance with minimum maintenance.

This machine is easy to operate for long duration due to its simple design &simple technology. As conveyor speed can be customized, machine speed &performance can be easily aligned with Labor's speed & performance.

Needless to say, sealed bags or pouches by Continuous Band Sealer produces accurate sealing without any leakage compared to any other sealing process.

Target Industries

- Food & Groceries

- Flour Mills

- Seeds

- Dairy Products

- Bakery Products

- Pharmaceuticals

- Chemical Industries

- Cosmetic Products

- Automobile Spare Parts

- Electronic Spares & Components

- Bearing Industries

- Pesticides

- Detergent

- Tobacco & many more...

Technical Specifications

| Machine Weight | 19 KGS |

| Brand | VIJAYPACK |

| Model Name/Number | VP 900 H-MS |

| Capacity | 1 KG |

| Automation Grade | Semi-Automatic |

| Max. Conveyor Load | 3 KGS |

| Motor Power | 650 W |

| Operational Mode | Horizontal |

| Temperature Range | 0 300 DEGREE C |

| I Deal In | New Only |

| Sealing Speed | 0 12 MTR. / MIN |

| Phase | SINGLE |

| Material | MS |

| Sealing Width Mm | 6 12 MM |

| Usage/Application | Heat sealing of a variety of thermoplastic pouches & bags |

| Temperature Controller | Electronic constant temperature control system |

Effortless Operation and Reliability

The semi-automatic horizontal band sealer combines user-friendly controls with consistent results. Built with a durable MS body, it can run continuously for high-volume packaging, maintaining 100% accuracy in seals. Its simplicity reduces training time and ensures smooth integration into existing workflows.

High Versatility Across Applications

Ideal for sealing all types of plastic bags and pouches, this machine is perfect for packaging needs in food, pharmaceuticals, chemicals, and retail. Its adjustable sealing speed (012 mtr/min) allows you to tailor the process according to material thickness and throughput requirements, enhancing operational flexibility.

Compact and Energy Efficient Design

The band sealer measures just 800 x 400 x 305 mm and weighs 19 kg, making it easy to position and relocate as required. Running on 220V and 650W, it is energy conscious, helping lower operating costs while delivering professional-grade seals every time.

FAQs of Band Sealing Machine:

Q: How does the horizontal band sealing machine operate?

A: The machine uses a heated band to seal the open edge of plastic bags or pouches. You simply insert the filled bag into the machine and it automatically feeds, seals, and discharges the bag at speeds up to 12 meters per minute, requiring minimal manual intervention.Q: What types of packaging materials are compatible with this sealer?

A: This band sealer is suitable for a wide variety of plastic bags and pouches, including those used in food, chemical, and pharmaceutical packaging. It can handle most common thermoplastic materials efficiently.Q: When is the machine most beneficial to use?

A: This machine excels in environments where rapid, consistent, and reliable sealing of large volumes of bags or pouches is requiredsuch as manufacturing plants, packaging units, or export operations. Its high speed and accuracy maximize productivity.Q: Where can I install this band sealing machine?

A: Due to its compact dimensions (800 x 400 x 305 mm) and lightweight design (19 kg), it can be set up on any sturdy table or dedicated workstation in packaging facilities, warehouses, and production sites.Q: What is the process for maintaining sealing accuracy and speed?

A: The machines semi-automatic controls allow you to adjust the sealing speed and temperature as per the thickness and type of material. Regular cleaning and calibration ensure the machine maintains its 100% sealing accuracy and optimal speed.Q: How does using this band sealer benefit my packaging process?

A: By automating the sealing function, you achieve uniform, airtight seals quickly and reliably, reducing manual errors, labor costs, and downtime. This enhances overall packaging efficiency and ensures professional product presentation.Q: Can the machine be used by different industries in India?

A: Absolutely. Its versatile design and ease of use make it suitable for distributors, exporters, manufacturers, suppliers, and traders across multiple sectors throughout India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Band Sealing Machines' category

|

VIJAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send SMS

Send SMS