Call Us

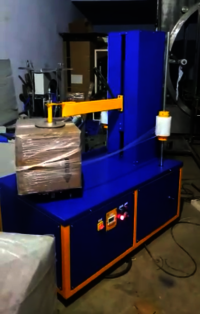

08045478157Box Wrapping Machine

Product Details:

- Product Type Box Wrapping Machine

- Computerized Yes

- Automatic Grade Semi-Automatic

- Color White, Yellow, Blue & Black

- Warranty Available

- Click to View more

Box Wrapping Machine Price And Quantity

- 1 Piece

- 395000 INR/Piece

- 75000.00 - 350000.00 INR/Piece

Box Wrapping Machine Product Specifications

- Available

- Box Wrapping Machine

- Yes

- White, Yellow, Blue & Black

- Semi-Automatic

Box Wrapping Machine Trade Information

- Kolkata

- 7 Piece Per Week

- 3 Days

- Yes

- Contact us for information regarding our sample policy

- Standard

- Asia, Africa

- Assam, Bihar, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Odisha, Sikkim, Tripura, West Bengal, Jharkhand, Chhattisgarh, All India

Product Description

Introduction

Vijaypack manufactures & supply a range of Box Stretch Wrapping Machine, which is designed to wrap carton boxes with LLDPE Stretch Film. This machine is widely preferred to minimize time, labor, stretch film consumption and increase productivity dramatically. This system is also effective to offer tight packaging and smooth finishing in compare to manual methods; thereby resisting transit pilferage, increasing brand value and securing goods / products from moisture and dust.

Salient Features

- Scratch Resistance

- Varied Sizes of Boxes / Cartons Can be Wrapped

- Auto / Manual Cycle Stop to Prevent Loss of Film

- User Friendly

- Speedy Production

- Economical Packing

- Easy Identification of Wrapped Product

- Low Maintenance

Advantages

The notable advantages of fully automatic stretch wrapping machines are mentioned below:

- It Is Time & Labor Saving, Thus, Highly Cost Effective.

- It Reduces Film Consumption from 33% - 50% As Compared to Manual Methods Depending upon the Type of Model; Thus, High Savings in Film Cost.

- High Production

Price Range:Rs. 75, 000/- to Rs. 3,50,000/-

Industrial Application

Box Stretch Wrapping Machine is most suitable to be used in a host of industries such as Newspaper, Book Publishers, Note Book, CFC Boxes, Fan, FMCG Product, Marine Industry, Foot Wear, Leather Industry, Offset Printing, Pharmaceutical, Garments, Food Processing & many more...

Versatile Color Options and Design

Choose from four appealing colorswhite, yellow, blue, or blackto match your workspace or branding requirements. The durable build and semi-automatic operation ensure both reliability and user-friendly handling for diverse packaging needs.

Enhanced Automation with Computerized Controls

This machine features computerized functionality, enabling precise and consistent wrapping with minimal manual intervention. The semi-automatic grade provides flexibility, making it ideal for small to medium enterprise applications where both speed and supervision are important.

Warranty and Service Support

Purchasing this Box Wrapping Machine includes warranty coverage for added assurance. As a manufacturer, distributor, and exporter based in India, we offer extensive after-sales support, ensuring lasting performance and customer satisfaction globally.

FAQs of Box Wrapping Machine:

Q: How does the semi-automatic box wrapping process work?

A: The semi-automatic box wrapping machine requires the operator to place the box on the platform and initiate the cycle. The machine then wraps the box efficiently using a stretch film, with computerized settings to maintain consistent tension and coverage.Q: What are the key benefits of using this box wrapping machine?

A: This machine enhances packaging speed, reduces manual labor, and delivers uniform wrapping for every box. Its computerized system optimizes film usage, which cuts down on material waste and supports cost-effective operations.Q: When is it best to use a semi-automatic rather than a fully automatic box wrapper?

A: A semi-automatic box wrapping machine is ideal when you need flexibility, occasional manual adjustments, or deal with varying box sizes and shapes. It suits operations that require operator oversight but benefit from partial automation for efficiency.Q: Where can I purchase or source this box wrapping machine in India?

A: This machine is available directly from us as a manufacturer, as well as through our distributor, exporter, supplier, and trader networks across India. International clients can also source the machine for export from our facility.Q: What is included in the warranty for this machine?

A: The machine comes with a warranty that covers manufacturing defects and system malfunctions for a specified period. This ensures reliable performance and provides users with support for repairs or replacements if necessary.Q: How does the computerized function improve the wrapping process?

A: The computerized features allow operators to set wrapping parameters precisely, ensuring each box is wrapped with the ideal tension and number of film layers. This boosts consistency and minimizes errors compared to manual controls.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

VIJAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send SMS

Send SMS