Call Us

08045478157Continuous Bag Sealer

Product Details:

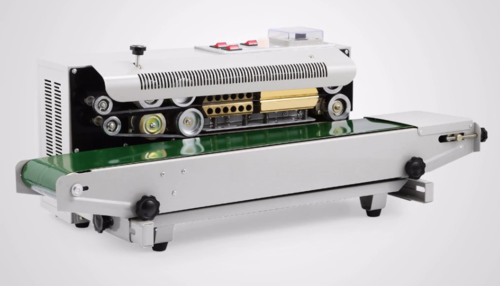

- Application Sealing Plastic Bags & Pouches

- Condition New

- Dimension (L*W*H) 880 x 420 x 350 Millimeter (mm)

- Type Horizontal Band Sealing Machine with Nitrogen Flushing Attachment

- Weight 1 Kilograms (kg)

- Accuracy 100 %

- Color Milky White & Green

- Click to View more

Continuous Bag Sealer Price And Quantity

- 1 Piece

- 33500 INR/Piece

Continuous Bag Sealer Product Specifications

- Semi Automatic

- 100 %

- 1 Kilograms (kg)

- 500 Watt (w)

- Horizontal Band Sealing Machine with Nitrogen Flushing Attachment

- 0 ~ 12 Mtr. / Min

- New

- Sealing Plastic Bags & Pouches

- Milky White & Green

- 880 x 420 x 350 Millimeter (mm)

Continuous Bag Sealer Trade Information

- Kolkata

- Telegraphic Transfer (T/T), Cash Advance (CA), Cash in Advance (CID), Cheque

- 5 Piece Per Week

- 3 Days

- Contact us for information regarding our sample policy

- Standard

- Tripura, Bihar, Assam, Arunachal Pradesh, Chhattisgarh, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Sikkim, West Bengal, East India, Jharkhand, All India

Product Description

Introduction

It is latest in sealing technology; and ideal for heat sealing of a variety of thermoplastic pouches and bags continuously, speedily & efficiently. It is a heavy duty model of Continuous Band Sealer, available in horizontal configuration with Nitrogen Flushing, which helps to keep foods fresh and prevents formation of bacteria and allergens. It is in great demand due to efficient packaging of both perishable and non-perishable products in terms of protection from potential damages and contamination before reaching at the hand of end customers.

It adopts electronic constant temperature control system and step less speed adjusting transmission mechanism. As an optional attachment, Solid ink wheel, which is provided, can print production date as well as sealing. The printing letters are clear, have available colours, dries immediately & easy to change.

Salient Features / Benefits

- Simple Design & Sturdy Construction

- MS Body

- Horizontal Sealing

- Low Maintenance

- High Productivity

- Reliable Sealing Quality

- Very Low Power Consumption

- Suitable for Pack Size of Upto 2 Kgs

- Suitable for All Type of Heat Sealable Material in Every Thickness

- Increased Shelf Life of Packaged Product

- Preserving Foods as Fresh

- Adjustable Digital Timer to Control Gas Flushing & Sealing

Advantages

Due to automation, Continuous Band Sealer is able to increase production dramatically. On an average, 20 to 30 plastic bags / pouches can be sealed in a minute. Sealing speed will depend upon operators' efficiency.

It can give output equivalent to 3-4 Manual Sealing Machines thus there is great savings in labour cost.

This machine is imported from Taiwan including best parts, components. It is manufactured in the highly developed manufacturing unit in using latest technology. Machine's quality is strictly controlled in various levels of manufacturing based on range critical parameters. Hence quality is assured for continuous,excellent & prolonged machine performance with minimum maintenance.

This machine is easy to operate for long duration due to its simple design &simple technology. As conveyor speed can be customized, machine speed &performance can be easily aligned with Labors' speed & performance.

Needless to say, sealed bags or pouches by Continuous Band Sealer produces accurate sealing without any leakage compared to any other sealing process.

Target Industries

- Food & Groceries

- Flour Mills

- Seeds

- Dairy Products

- Bakery Products

- Pharmaceuticals

- Chemical Industries

- Cosmetic Products

- Automobile Spare Parts

- Electronic Spares & Components

- Bearing Industries

- Pesticides

- Detergent

- Tobacco & many more.

Technical Specifications

| Machine Weight | 32 KGS |

| Brand | VIJAYPACK |

| Model Name/Number | VP 770 H-MS NF |

| Capacity | 1 KG |

| Automation Grade | Semi-Automatic |

| Max. Conveyor Load | 3 KGS |

| Operational Mode | Horizontal |

| Power | 500 W |

| Sealing Speed | 0 12 MTR / MIN |

| Size | 8,10 MM |

| Material | MS BODY |

| Usage/Application | Heat sealing of a variety of thermoplastic pouches |

| Temperature Controller | Electronic constant temperature control system |

Advanced Sealing for Varied Industries

Engineered to meet the demands of food, pharmaceutical, and general packaging sectors, this semi-automatic horizontal band sealer offers consistent performance. Its nitrogen flushing functionality ensures extended shelf life by reducing oxidation within sealed bags. With a user-centric design and robust construction, it handles high volumes efficiently, making it a versatile option for businesses seeking quality and reliability in sealing operations.

User-Friendly Operation and Maintenance

The machine boasts a straightforward setup and intuitive controls, making it simple for operators to use with minimal training. Routine maintenance is easy, thanks to accessible components and a durable MS body that withstands everyday industrial use. This ensures long-term functionality and cost-effective operation, reducing downtime and streamlining maintenance procedures.

FAQs of Continuous Bag Sealer:

Q: How does the nitrogen flushing feature benefit my packaging process?

A: The nitrogen flushing attachment displaces oxygen inside the bag before sealing, preserving product freshness, extending shelf life, and preventing spoilage, particularly useful for food and sensitive commodities.Q: What types of materials can this continuous bag sealer handle?

A: This machine is designed for sealing plastic bags and pouches, making it suitable for a wide range of packaging needs across different industries.Q: When is maintenance required and how do I maintain the sealer?

A: Routine maintenance should be performed based on usage frequency, typically including cleaning the sealing bands, checking for wear, and lubricating moving parts. The MS body ensures durability, requiring minimal upkeep.Q: Where can this machine be installed for optimal use?

A: With a compact dimension of 880 x 420 x 350 mm, it can be installed on production floors, packaging rooms, or assembly lines. Its sturdy build ensures reliable performance in various operational environments.Q: What is the process for operating the semi-automatic band sealer?

A: Simply set up the machine, adjust the sealing speed and temperature as needed, position the filled bag on the conveyor, and let the band sealer automatically seal and flush nitrogen as required.Q: What are the main benefits of using this horizontal band sealing machine?

A: It offers high-speed and accurate sealing (up to 12 meters per minute), robust build quality, user-friendly controls, and extended product freshness with nitrogen flushing, enhancing overall packaging efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Band Sealing Machines' category

|

VIJAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send SMS

Send SMS Call Me Free

Call Me Free