Call Us

08045478157Pallet Stretch Wrapping Machine

Product Details:

- Product Type Pallet Wrapping

- Automatic Grade Semi-Automatic

- Voltage 440 Volt (v)

- Rotating Speed 0 ~ 10 RPM

- Dimension (L*W*H) 2500 x 1500 x 2100 Millimeter (mm)

- Weight (kg) 750 Kilograms (kg)

- Warranty Black

- Click to View more

Pallet Stretch Wrapping Machine Price And Quantity

- 1 Piece

- 372000.00 INR/Piece

Pallet Stretch Wrapping Machine Product Specifications

- Semi-Automatic

- 750 Kilograms (kg)

- Black

- 0 ~ 10 RPM

- 2500 x 1500 x 2100 Millimeter (mm)

- Pallet Wrapping

- 440 Volt (v)

Pallet Stretch Wrapping Machine Trade Information

- Kolkata

- Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- 5 Piece Per Week

- 3 Days

- Yes

- Contact us for information regarding our sample policy

- Standard

- Asia, Africa

- Tripura, Manipur, Assam, Arunachal Pradesh, Mizoram, Meghalaya, Nagaland, Sikkim, West Bengal, Madhya Pradesh, Bihar, Odisha, Jharkhand, Chhattisgarh, All India

Product Description

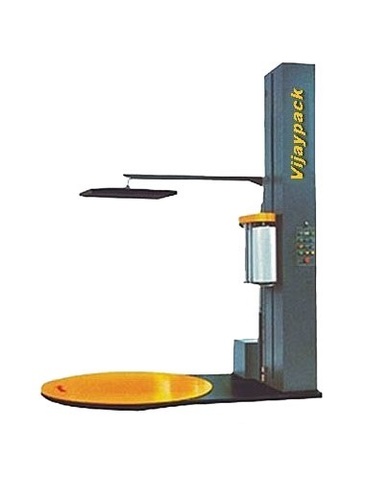

Pallet Wrapping Machine (VP 2000 B)

Introduction

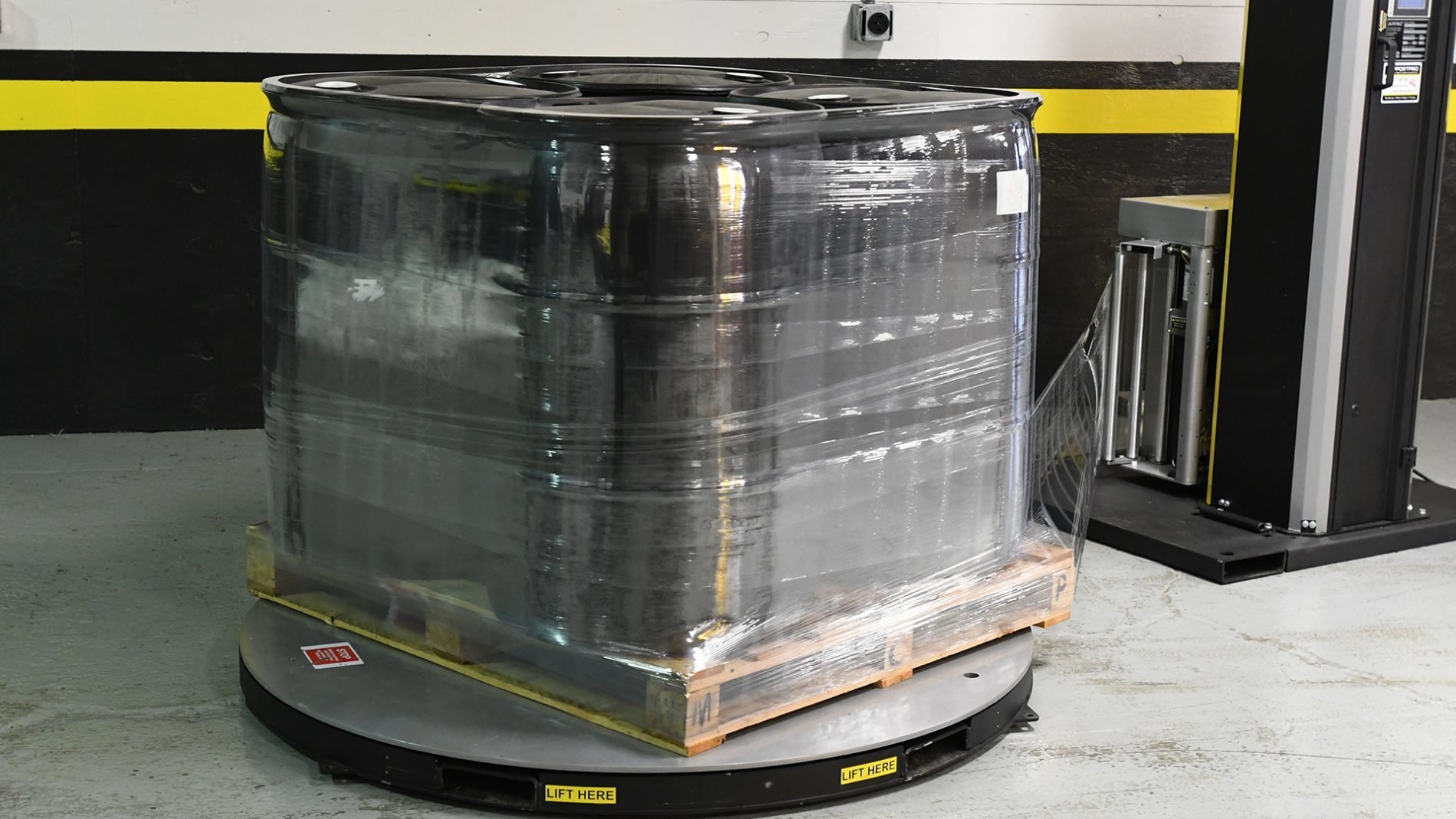

Vijay Pack introduces Pallet Stretch Wrapping Machine, which is capable to wrap pallets of varied sizes & loads easily & swiftly. It helps to save time, labor & film as compared to manual methods. This Stretch Wrapping System ensures tight packaging & thus provides safe transportation of Palletized Cargo. It is also reliable to resist in transit pilferage. It also provides good protection for goods/ products from the moisture & dust even if stored for a long period of time. Needless to say, it is an exceptional innovation of stable & scratch resistant packing to ensure that end customers receive packages / products in the safest way.

Salient Features/ Benefits

- This Machine Is Designed to Wrap Pallets with LLDPE Stretch Film

- Robust Construction

- Power Stretching (Controllable) Up to 300%

- PLC Controlled

- Controllable Cycle Time

- Safety Features Incorporated

- Auto / Manual Cycle Stop

- User Friendly

- Low Maintenance

Advantages

- Speedy Packing: By using this machine 200-250 Pallets / Day can be packed easily, thus,productivity is increased 5-10 Times as compared to manual methods.

- Labor Cost Savings: Only one layman is enough to operate automatic pallet stretch wrapping machine, which includes bringing the Palleton to the Wrapping Machine by using Handheld, Hydraulic or Battery Operated Pallet Truck. Hence, using this machine an organization can increase productivity by 5-10 Times only at the cost of one labour.

- High Longevity of Product: As Vacuum Packaging System removes air from the packaged product, thus increases shelf life of highly perishable products like Paneer, Cheese & Meat etc.

- Material Cost Saving: In automatic system, film can be stretched upto 250 - 300% due to motorized power stretch system, which results insubstantial savings in film consumption, thus helping an organization to save substantial amount.

- Better Finishing: This system gives completely smooth and uniform packing. The wrapping is much tighter due to use of power stretch technology thus resulting in better finishing as compared to manual stretch wrapping.

- Safety: Due to uniform and tight packing there are very less chances of film or package becoming loose in transit and hence package safety is much higher either during inland transportation or long high seas export shipment.

Price: Rs. 3,72000/-

Industrial Application

Food Processing, Beverages, Refractories, Warehousing & Logistics, Non Ferrous Metal Ingots viz Aluminum/ Lead/ Copper, Paper Mills, Foundry, Textiles,Medium & Heavy Engineering Industries, Chemical bags & many more.

Technical Specifications

|

I Deal In |

New Only |

|

Power |

2 KW |

|

Usage/Application |

Wrapping pallet of varied sizes & loads easily & swiftly |

|

Turntable Speed |

0 ~ 10 rpm |

|

Model Name/Number |

Vp 2000 a |

|

Packaging Size |

L 1500 x w 1500 x h 2000 |

|

Stretching Type |

Mechanical |

|

Packing Weight |

1500 kgs |

|

Brand |

Vijaypack |

|

Automation Grade |

Semi automatic |

|

Machine Size |

L 2500 mm x w 1500 mm x h 2100 mm |

|

Phase |

3 phase |

|

Surface Finished |

Smooth |

|

Voltage |

440 v |

|

Weight |

650 kgs |

Efficient Semi-Automatic Pallet Wrapping

Streamline your packaging process with this semi-automatic pallet stretch wrapping machine. Built to offer reliable operation, it wraps loads securely while reducing manual labor. Ideal for high-volume businesses, it increases throughput and packaging consistency, making it a suitable choice for Indian manufacturers and suppliers seeking to enhance efficiency.

Rugged Design and Versatile Application

Constructed with a heavy-duty frame and a 750 kg footprint, the machine ensures stable operation even during demanding packaging cycles. Its adjustable rotating speed (010 RPM) and sizable turntable can accommodate large pallets, making it perfect for warehouses, distribution centers, and export facilities throughout India.

FAQs of Pallet Stretch Wrapping Machine:

Q: How does the pallet stretch wrapping machine improve packaging efficiency?

A: The machine automates the wrapping process, ensuring consistent stretch film application around pallets, which reduces manual effort, speeds up packaging time, and minimizes film waste.Q: What is the installation process for this machine in a typical warehouse setting?

A: Installation involves placing the machine on a level surface with adequate space (minimum 2500 x 1500 x 2100 mm), connecting it to a 440-volt power source, and following manufacturer setup instructions for calibration and testing.Q: When should the wrapping speed be adjusted, and how?

A: The rotating speed (010 RPM) should be adjusted based on pallet load weight, film type, and required tension. Lighter or unstable loads benefit from slower speeds, while stable, heavier loads can use higher speeds for quicker wrapping.Q: Where can this stretch wrapping machine be used most effectively?

A: This machine is best suited for use in warehouses, manufacturing plants, export houses, and distribution centers where high-volume palletizing and consistent load security are vital.Q: What are the main benefits of using this semi-automatic wrapping machine?

A: Key benefits include enhanced load security during transport, reduced packaging time, lower labor costs, and decreased film consumption due to efficient, uniform wrapping.Q: How is the machine supplied and supported in India?

A: It is distributed, exported, and supplied by reputable manufacturers and traders across India, each offering product support, warranty, and after-sales service to ensure optimal uptime and reliability of the equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Pallet Wrapping Machines' category

|

VIJAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send SMS

Send SMS